Advantages

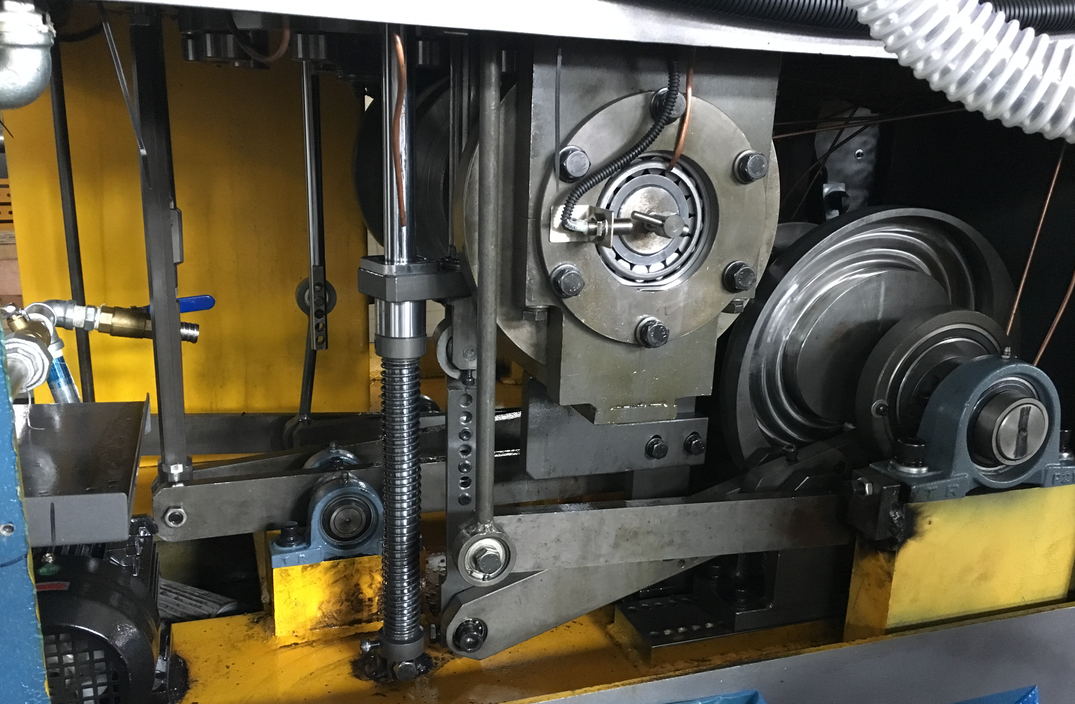

1.The whole steel plate fuselage, interlayer paper feeding design and the style of oil poured lubrication system is Ensured the equipment long-term normal and Stable Work

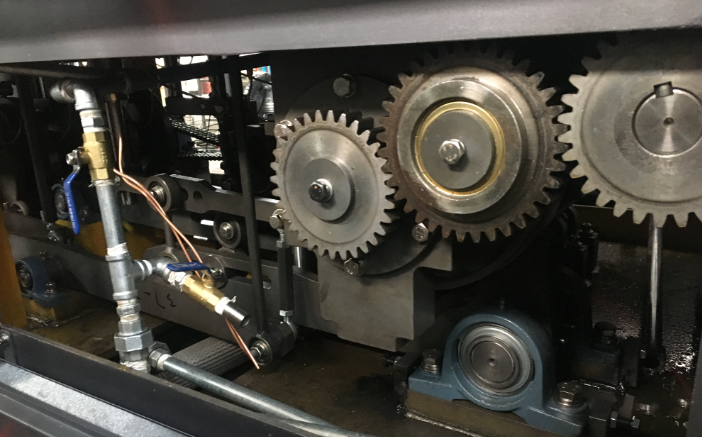

2.Short distance double vertical axis combine advanced and high-precision cylinder open type cam drive make every stations high-speed worked accurate without mistake

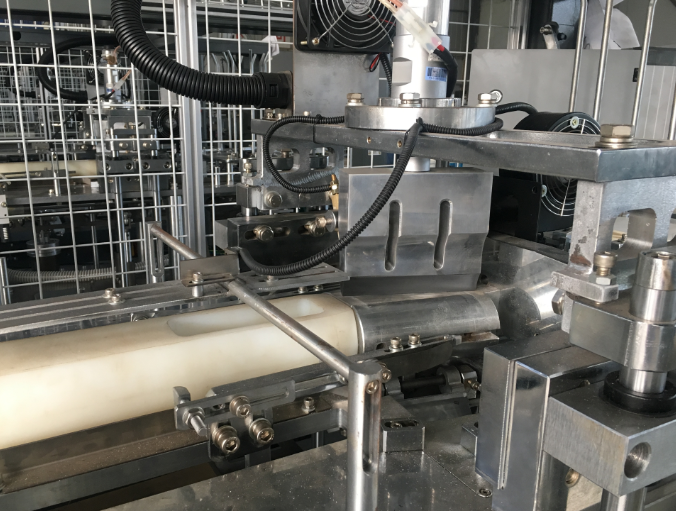

3.Single wrap the leaf groove cam structure combine seesaw roof bar design can make the high-speed paper feeding go to the place accurately

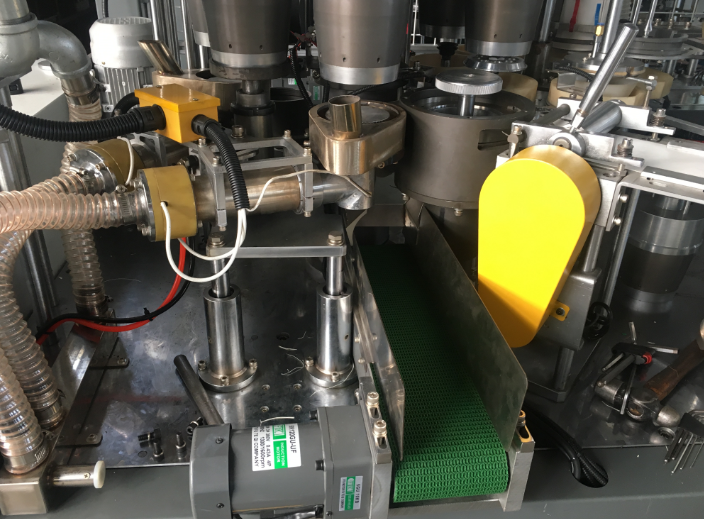

4.Exquisite original creation ¢490mm mould turn plate design make the equipment work load more light and the speed to be more fast

Technical parameter

|

Model |

JBZ-35S |

|

Cup size |

6-44OZ |

|

Raw material |

Single and double PE coating paper |

|

Paper thickness |

Body: 160-300gsm Bottom: 150-230gsm |

|

Top mouth diameter |

90mm-140mm |

|

Bottom diameter |

80mm-115mm |

|

Bottom depth |

5mm-10mm |

|

Height |

45mm-110mm |

|

Angle |

4-8° |

|

Capacity |

70-100 pieces per minute |

|

Main motor power |

2.2kw |

|

Total power |

17.5kw |

|

Energy consumption |

9.5 kw / hour |

|

air consumption |

0.4m3/min, 0.5-0.8Mpa |

|

Weight |

3500kg |

|

Dimension |

2910x1400x1800mm |

Machine detail:

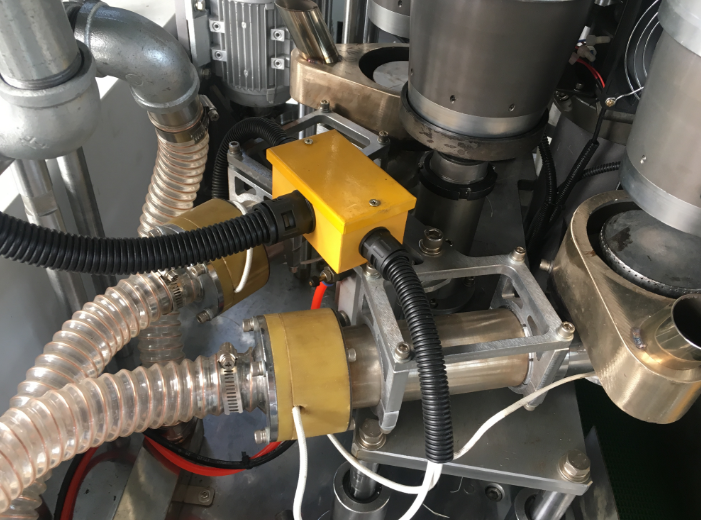

1.Open cam transmission system. Unique hanging cam design to reduce pollution.

2.Automatic lubrication system. Save your labor and easier your daily work.

3.Aluminum Mold, longer using life with less abrasion.

4.Ultrasonic unit guarantee fast and good quality sealing.

5.Bottom paper feeding uses servo motor.

6.Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

7.PLC control system