Main features

• The automatic cup feeding and conveying device is simple and convenient to operate, convenient, humanized and labor-saving.

• It is convenient and smooth to adjust the cup under the cup.

• The printing roller is automatically separated in the state of no cup and double cup, which reduces downtime and saves time.

• The gear clearance of the plate roller is appropriate, and the printing wheel plate roller has no clearance, so that the printing cup is clearer and more reliable.

• Printing plate punching is equipped with a special punching machine, which is accurate, fast and easy to operate.

• The cup mold is convenient to replace and easy to operate, which saves the replacement time to the greatest extent.

• Pre-press corona treatment has the function of detecting broken cups, which can better prevent unqualified products from flowing into the next link.

• In the printing process, it also has the function of non-stop sampling inspection and printing effect detection.

• The photoelectric correlation technology is accurate and convenient to count.

• Double motors and double frequency conversion control, which can switch split debugging and testing at will.

Applocation

The equipment is suitable for external color printing and packaging coating color printing of milk tea, cheese, yogurt cups, ice cream, breakfast porridge cups, bowls and other utensils.

Technical parameter

|

Model |

JYJ-180-6D |

|

Printing diameter |

¢45 - ¢180mm |

|

Cup inclination |

3-13degree |

|

Maximum printing speed |

200-400 PCs/min |

|

Diameter of cup mouth |

Dia.45--180 mm |

|

Cup height |

25-190mm |

|

UV Curing power |

6 KW |

|

Power of main motor (double motor and double frequency conversion control) |

5.5 kw-4kw |

|

Total power |

21 kw |

|

Machine weight |

About 7500kg |

|

Machine dimension |

L7000*W2600*H2500mm |

Machine Details:

|

|

|

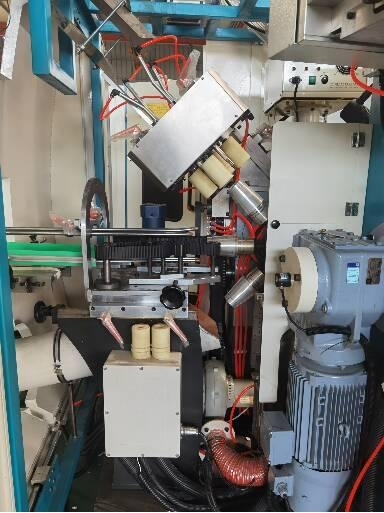

Cup inlet and outlet device |

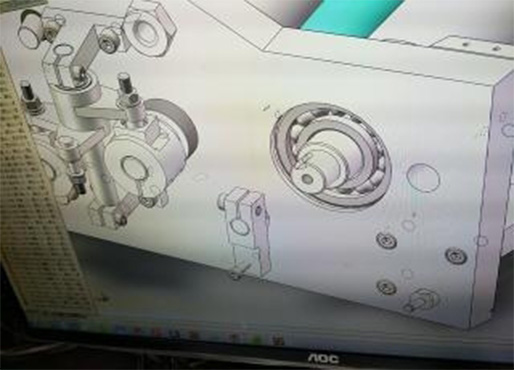

Ink transfer device part |

|

Send the quilt into the printing area, and send the printed cup out after the quilt is printed. This device ensures that the cup maintains a stable position and orientation during the printing process, thus guaranteeing printing quality and efficiency. During the printing process, the cup inlet and outlet device can also help adjust the position of the cup so that it is aligned with the impression of the press to ensure that the printed pattern is accurately printed on the cup. |

The ink transfer device is a crucial part of the cup press, which is responsible for transferring the ink to the surface of the printed cup, affecting the printing quality and efficiency. The reasonable design and coordination of each component can ensure the uniform transfer of ink and stable printing, improve printing quality and production efficiency. |

|

|

|

|

Cup-feeding device |

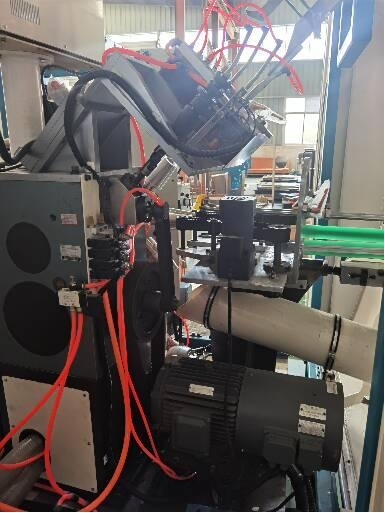

Cup-separating device |

|

The cup feeder is used to transport the cups to be printed from the storage area to the working area of the press. The conveyor belt is usually used to ensure that the cup is transported in a stable and orderly manner during the transportation process. |

The cup separation device plays a key role in the cup printing press, which can realize the functions of cup separation, alignment, conveying and so on, and provide a reliable supply of cups for the subsequent printing process, thereby improving production efficiency and printing quality. |

|

|

|

|

Corona treatment device |

Printing adjustment part |

|

Corona treatment device is a device used to treat the surface of printed matter, mainly used to improve the adhesion of printed matter and surface treatment effect. In the printing industry, corona treatment devices are usually used to treat the surface of materials such as plastic, glass, and metal to enhance their surface tension and improve the adhesion of printing inks. |

It is mainly used to adjust the impression or plate of the printing press to ensure that the parameters such as printing position, printing pressure and printing quality are in the best state. To ensure that the cup printing machine can be stable and efficient printing work, to ensure the quality of printed matter and production efficiency. |

|

|

|

|

Color group plate roller |

UV curing part |

|

Color plate roller is a common equipment component in the printing industry, used to separate and transfer different colors of ink to the surface of the printing material to achieve multi-color printing |

UV curing is a commonly used printing process that rapidly cures and dries ink or paint on the surface of a printed material by using an ultraviolet (UV) light source. |

Print product display

Spare parts of machine

|

名称Name |

品牌Brand |

所属地Brand’s Country |

|

空气开关 Air Switch |

正泰Chint |

中国China |

|

塑料壳断路器 |

正泰Chint |

中国China |

|

固态继电器Intermediate Relay |

阳明FoTek |

台湾Taiwan |

|

交流接触器AC Contactor |

正泰Chint |

中国China |

|

热过载继电器 Thermal Overload relay |

正泰Chint |

中国China |

|

按钮Button |

施耐德Schneider |

法国France |

|

指示灯 Indicator Light |

施耐德Schneider |

德国Germany |

|

PLC |

西门子Siemens |

德国Germany |

|

控制模块Control Module |

西门子Siemens |

德国Germany |

|

触摸屏 Touch Screen |

西门子Siemens |

德国Germany |

|

主电机 1 Main motor ( first) |

西门子(贝得)Siemens |

德国Germany |

|

开关电源Switching power supply |

明纬MW |

台湾Taiwan |

|

光电开关Photoelectric switch |

欧姆龙Omron |

日本Japan |

|

接近开关Proximity Switch |

欧姆龙Omron |

日本Japan |

|

变频器 Frequency Converter |

欧瑞OuRui |

台湾Taiwan |

|

电磁阀 Solenoid Valve |

亚德克AirTac |

台湾Taiwan |

|

电磁阀Solenoid Valve |

亚德克AirTac |

台湾Taiwan |

|

气缸Air Cylinder |

亚德克AirTac |

台湾Taiwan |

|

主电机2 Main Motor ( Second) |

大速DASU |

中国China |

|

同步带Synchronous Belt |

宁波贝蒂BD |

中国China |

|

轴承Bearing |

NTN、NSK、哈尔滨 |

中国China |

|

急速小电机 |

展鹏Zapn |

中国Cuina |

|

联轴器 |

光大 |

中国Cuina |