JBZ-22D/22S Automatic paper cup forming machine

Features:

1.The whole steel plate fuselage、interlayer paper feeding design and the style of oil poured lubrication system is Ensured the equipment long-term normal and Stable Work;

2.Short distance double vertical axis combine advanced and high-precision cylinder open type cam drive make every stations high-speed worked accurate without mistake;

3.Single wrap the leaf groove cam structure combine seesaw roof bar design can make the high-speed paper feeding go to the place accurately;

4.Exquisite original creation ¢490mm mould turn plate design make the equipment work load more light and the speed to be more fast;

5.Scientific and reasonable mechanical is fit Itinerary design can using in premise of exchange mould can make the products producing range 6oz-22oz ;paper thickness 170g-350g .

Maintenance:

1.The equipment basic fixed point is focus on table-board,can adjust and change the parts of table-board directly ,it's convenient maintain and operate;

2.The equipment shape design small volume,small floor space,greatly save the client's factory using space;20 cabinet can install 4 cabinet can efficient decrease client transport fees;

Technical Parameters:

| Model | JBZ | |

| Cup size | 6-22oz | 6-22oz |

| Raw material | 160-350g/m2 (single side PE coated paper) |

160-350g/m2 (Double side PE coated paper and single side PE coated paper) |

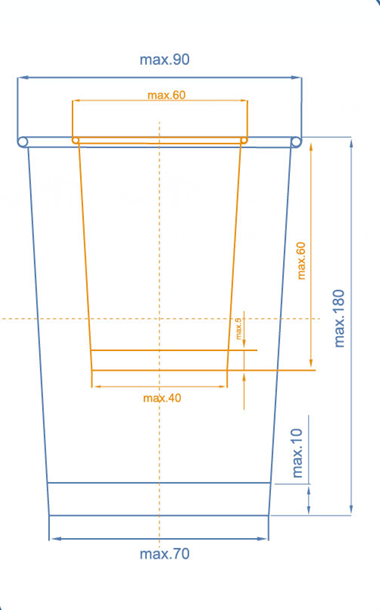

| Top mouth diameter | φ60mm-φ90mm | φ60mm-φ90mm |

| Bottom diameter | φ40mm-φ70mm | φ40mm-φ70mm |

| Height | 60mm-180mm | 60mm-180mm |

| Bottom depth | Depth 5mm-10mm | Depth 5mm-10mm |

| Capacity | 60-90 pcs/min | 60-90 pcs/min |

| Main motor power | 1.5kw | 1.5kw |

| Energy consumption | 6-6.5kw/h | 6-6.5kw/h |

| Total power | 11.5kw | 11.5kw |

| Air source | 0.4m³/min,0.5-0.8Mpa | 0.4m³/min,0.5-0.8Mpa |

| Weight | 2200Kg | 2200Kg |

| Dimension(L*W*H) | 1750mm*1350mm*1850mm | 1750mm*1350mm*1850mm |