BDFQ-D Series

Computer High-Speed Slitting Machine

Application:

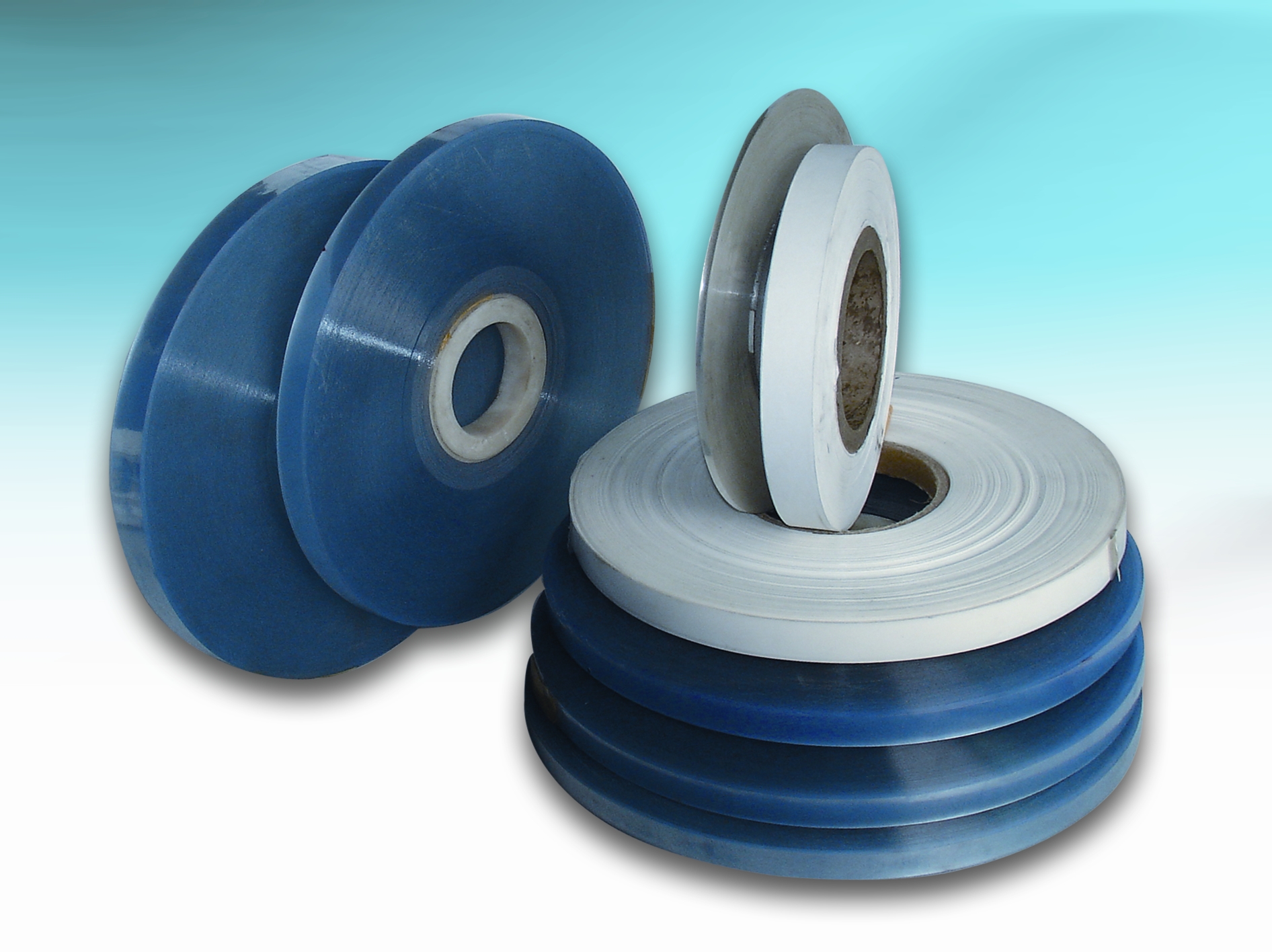

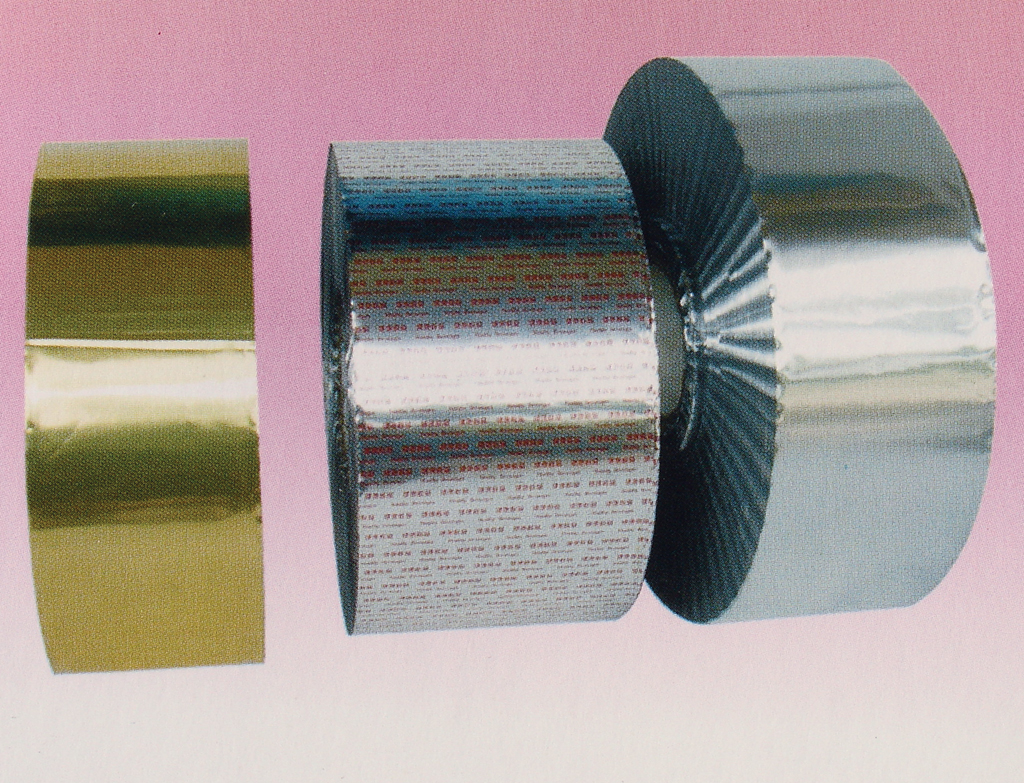

This machine is used for slitting and rewinding various large rolling materials such as paper,(10g/㎡-500g/㎡)cellophane paper,bill paper, OPP,PET,FILM,Aluminun foil ,plastic ,Non woven ,Fabric , Copper foil etc.

Performance and Characteristics:

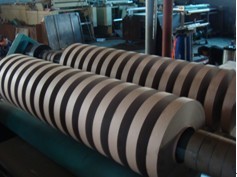

1.This machine use three servo motor control , automatic constant tension, central surface reeling. High speed 350m/min

2.Frequency converter timing for main machine,keeping speedup and stable operation.

3.It has the functions of automatic metering, automatic alarm, etc.

4.Adopt A and B pneumatic shaft structure for rewinding, easy for loading and unloading.

5.It adopts photoelectric automatic error correction adjustment system for unwinding, anomalistic materials will be easy slit.

6.Equipped with automatic waste film blowing device by circle blade(or vertical blade)

7.Automatic pneumatic airshaft loading

8.PLC control (Siemens brand) auto meter counting and stop

Main Technical Parameters:

|

Model |

BDFQ-1100D |

BDFQ-1300D |

BDFQ-1600D |

|

Max.width of unwinding |

1100mm |

1300mm |

1600mm |

|

Max.Diameter of unwinding |

1400MM |

1400MM |

1400MM |

|

Pneumatic air shaft loading |

|||

|

Max.diameter of rewinding |

¢550mm |

¢400mm |

¢400mm |

|

Min.width of slitting |

5mm |

5mm |

5mm |

|

Speed |

250-350m/min |

250-350m/min |

250-350m/min |

|

Total power |

17.0kw |

17.0kw |

17.0kw |

|

Weight (approx.) |

2300kg |

2500kg |

2800kg |

|

Dimension (L×W×H )(mm) |

3800×1700×1500(mm) |

3800×1900×1500(mm) |

3800×2200×1500(mm) |

(Other width of unwinding ,we can producing according to client’s request)

1) Unwinding is Shaft less loading system ,maximum diameter can be 1000 mm

Can be with 3”, 6” paper core

2)Round cutters for Aluminum foil ,paper etc:

(For film Plastic PVC etc will be vetical blade,the machine can be with both two balde together ,no need discharge them when exchange the material rolls )

The minimum width can be 5mm with vertical blade(razor)

The Minimum width can be 10mm with circle blade

3)Two Surface Riwinding Shafts Structure very good slitting surface:

1.Paper( slitted by circle cutter)

Rewinding shaft one side is connecting with machine, another side can be removed for very convenient discharge ( also two side can be removed when rewinding rolls is big and heavy)

Rewinding shaft one side is connecting with machine, another side can be removed for very convenient discharge ( also two side can be removed when rewinding rolls is big and heavy)

Control system ( PLC control made in Siemens )

With full automatic tension control , Auto meter counting , and auto stop when reach the meters of rewinding [ Language can be Chinese and English ]

Electrical parts :

Germany Siemens PLC control and French Schneider parts

Main Machine Parts Specification:

|

Description |

Specification |

Number |

Brand original |

|

Rewind servo motor |

3.7KW |

2 sets |

Zhima |

|

Traction servo motor |

3.7KW |

1set |

Zhima |

|

Unwind brake by air |

10KG |

1set |

Shanghai |

|

Bearing |

|

1 group |

NSK Japan |

|

Pneumatic parts |

|

1 group |

SMC Japan |

|

Air valve |

|

2unit |

SMC Japan |

|

CCD error controller |

|

1 unit |

|

|

PLC |

CPU224XP |

1 unit |

Siemens Germany |

|

10 inch touch screen |

TPC1061Ti |

1unit |

Taiwan |

|

Switch |

|

|

OMRON Japan |

|

Low voltage electrical parts |

|

1 group |

Schneider France |

|

Switch power |

S100-24 |

1pc |

Mean Well Taiwan |

Parts list:

|

Enclosed on machine |

||||

|

No. |

Description |

Spec. |

Quantity |

Remarks |

|

|

Rotary cutter sets for paper, Aluminum foil etc |

|

10pc |

|

|

|

Rotary blade |

|

10pc |

|

|

In tool box |

||||

|

3 |

Air neb of air shaft |

|

5pcs |

|

|

4 |

Monkey wrench |

|

1 pc |

|

|

5 |

Ringent wrench |

12×14 |

1 pc |

|

|

6 |

Ringent wrench |

17×19 |

1 pc |

|

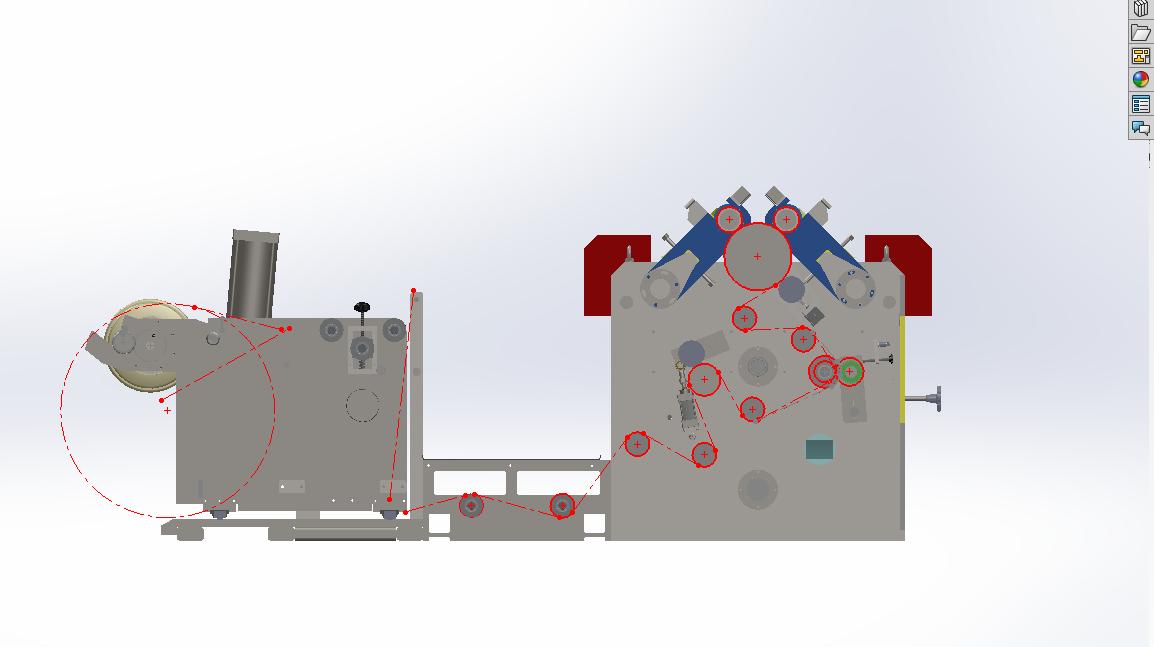

Machine structure drawing:

Working video:

BDFQ-1100D Slitter and Rewinder for aluminium foil

BDFQ-1100D Slitter and Rewinder for paper

BDFQ-1100D Slitter and Rewinder for plastic film