QUOTATTION

| DESCRIPTION | QTY | UNIT PRICE(USD) |

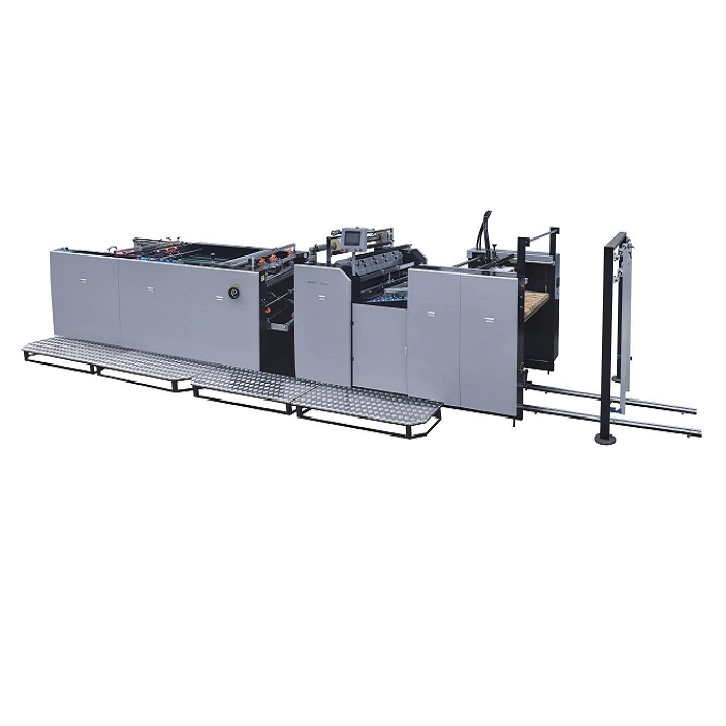

| MODEL:XF- 3200 SINGLE SIDE EXTRUSION LAMINATING MACHINE |

1SET | 580,000.00 USD/SET, CIF Mundra port,INDIA |

| Delievery time | 50 workdays after receive deposit | |

| Payment term | T/T50% in advance and T/T50% Before shipment or L/C 100% at sight | |

| Quotation valid | 15 days | |

Technical Parameter

| Suitable coating film resin | PE,PP |

| Base material | NON-WOVEN FABRIC |

| Max production speed | 200mm/min(Depends on the thickness of coating and base material) |

| Max. width of coating film | 3100mm |

| Thickness of film | 0.01-0.10mm |

| Coating thickness error limit | ±5% |

| Tension range setting | 10-150kg/entire width (constant tension) |

| Max extrusion output | 380kg/h |

| Compound cooling roller | ¢560mm |

| Length of die | 3250mm |

| Clearance of die lip | 0.8mm |

| Total power about | 80kw |

| Total power of the whole machine | About 130kw |

| Max rewinding diameter | ¢1300mm |

| Inside diameter of base material | ¢76mm |

| Weight | 20000kg |

| Overall dimension(L×W×H) | 11000mm×12000×3350mm |

| Machine color | Customer demand |

Configuration and Specification

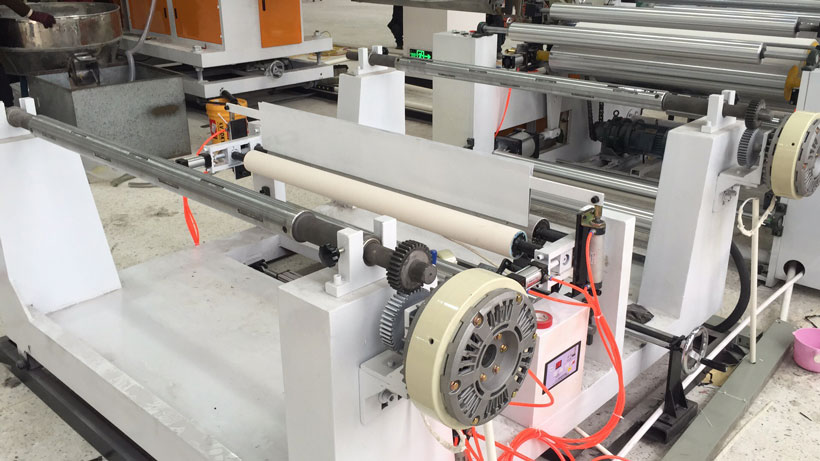

1.The first feeding device

Structure

Double stations feeding frame

Bearing supports the unwinding inflatable shaft

Gas type correcting control system

Semi-automatic splicing device

Tension controller

Specification

| Max feeding diameter | ¢1300mm |

| Tension setting | 100N.m |

| Tension control accuracy | ±0.2N.m |

| Magnetic powder brake | 2 sets(,Ruian) |

| Tension control brake | 2 sets (Made in Guangzhou) |

| Air-expansion feeding shaft | ¢74mm |

| Gas type correcting control system | 1 set (Taiwan Xinhe) |

| Rectify distance | ±75mm |

Characteristic

①Tension control baker: Input parameters according to the size of replace material, It can automatically proportional decreasing to achieve automatic tension control

②Semi-automatic feeding device without stopping unwinding,reduce the scrap rate in production.

2.AdjuvantBOPPGU-ci membranes Put a roll of device 1

Structure

Double stations feeding frame

Gas type correcting control system

Tension controller

Specification

| Max feeding diameter | ¢700mm |

| Tension setting | 100N.m |

| Tension control accuracy | ±0.2N.m |

| Magnetic powder brake | 2 sets(,Ruian) |

| Tension control brake | 2 sets (Made in Guangzhou) |

| Air-expansion feeding shaft | ¢74mm |

| Rectify distance | ±25mm |

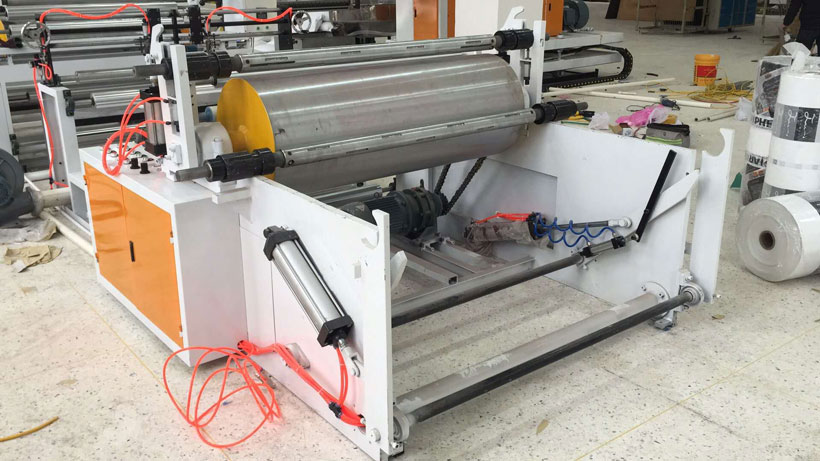

3. Extrusion and compounding device 1

Structure

①Three roller laminating compounded structure, and back pressure roller makes compound roller to force evenly and compound firmly.

②Peeling off silicone roller: compounded products peels off from cooling roller easily.

③Compounding & filling regulating roller can overcome defects such as uneven of film thickness.

④Compounding and discharging eliciting roller.

⑤Compounding roller is to be drived by frequency converter motor independently.

⑥The compounding roller driving motor is to be controlled by frequency converter .

⑦Check the cylinder buffering floating pendulum roller tension

Structure

Compounding roller: ¢560mm×3200mm, 1 piece,Shanghai CNC

Material:Seamless steel tube,Plating chromium on the surface,adopts sub-light processing,the cooling structure is screw type.

Silicone roller: ¢250×3200mm,1 piece,Wuxi,Material is compound silica,internal cooling structure.

Back pressure roller: ¢160×3200mm,1 piece.Material is seamless steel tube,plating chromium on the surface,internal cooling

structure

Compounding cylinder ¢160×100,2 pcs

Peeling roller,¢100×3200mm,1 piece

Motor,22kw

Frequency converter.22KW

Rotating joint,6 pcs,(Tengzhou Shandong)

Characteristic

Cooling roller adopts screw type cooling structure,cooling speed quickly and laminating easier.

Vector frequency converter motor drives independly, which can adjust the speed of the main motor .Not only satisfy the different thickness requirement of laminating products, also assure the thickness and degree of homogeneity are the same.

4.Extrusion device

Structure

Trolley type extrusion machine

Clothes-hanger type die head,Huangyan mould,Zhejiang

Feeding device:Automatic feeding device

Extrusion machine can move back and forth, up and down.

Screw and charging barrel linkage area are all heated with tungsten wire

High power and helical gear speed reducer

emperature is controlled by Digital temperature controller automatically(changzhou)

9heating zones are to control temperature of screw and charging barrel independently.

11 heating zones are to control the temperature of inner die head independently.

Specification

Effective width of die head is 3250mm of straight tube type, width of laminating:1600-3100mm.

Screw diameter: Φ145

L/D: 33:1

Frequency converter ,90kw, 1set

Motor,90KW, 1set

Characteristic

T-die is made by the electroplating to make the average and smooth laminating

Larger length-diameter ratio makes resin plasticizing more thoroughly, to assure the peeling strength.

8.Cutting head device

Round knife cylinder ¢40×25

Iadder-shapped screw barra I with static-across-cut by adju sting width of film

Surface hardness cutting roller

A high pressure fan

9.rewinding device

Structure

Surface winding device,double stations

Surface winding roller drives independently

Driving motor

Frequency control

Check the cylinder buffering floating pendulum roller tension

Specification

Rolling diameter:¢1300mm

Core diameter:¢76mm

Surface winding roller,high precision hard chrome plating roller:¢560x2200mm

Motor:22kw

Frequency converter:22KW

Rolling shaft clamping cylinder:¢100mm

Floating cushion cylinder:40x125mm(AIRTAC,Taiwan)

Inflatable unwinding shaft:¢74,2 pcs

Characteristic

Cylinder cushion floating pendulum roller tension detection, precision positioner feedback to drive the implementation of the composite synchronous machines, synchronize the tension stability and ensure a consistent winding tension, winding neat .

10.Others

Guide roller: Adopt the balance guide rollers

Pneumatic elements: Adopted import goods

Low-voltage components: all are UC Certified products.(Omron)

Supply the operating instruction,foundation drawing,electrical drawing with the machine

11.Assistant parts are prepared by user

Compressor:15w,including refrigerator,cooling tower,pump.

Power:Three phases,380V,50HZ,220A,110KW(three phase five wire system)

Air pressure: 6~8/kg/cm2

Water: 2~3kg/cm2

12、Exclusive items

(1)Project of Equipmet place and basic foundation work

(2)Project of supplying electric power tomachine controller cabinet

(3)Project of supplying water in-let to machnie

(4)Project of smoke-extraction for T die

(5)Tools of loading﹠uploading paper from rolling﹠rewingding

(6)Other projects not listed in the contract. Pneumatic slitting with round blade

13、Technical assurance and acceptance

Assure the performance,specification,quality and acceptance standards as following,

A:Performance and specification

(1)Resin:HDPE、LDPE、EVA、EAA、PP,etc.

(2)Base material:non-woven fabric40-300g/㎡

(3)Thickness of coating film:Min is 0.012mm,Max is 0.05mm(LDPE)

(4)Width of finished barrel:Max is 800mm,min is 300mm

(5)Extrusion output:LDPE is 200kg/hr.Temperature of resin is 300~340℃

(6)Recombination speed:Max is 100m/min in normal operation

(7)Tension of unwinding:Max is 40kg.

(8)Max winding and unwinding is 1300mm

B:Machine work and assembly accuracy

(1)All the surface of processing are grinded carefully and hardening treatment

(2)All of the rollers are static and dynamic balance processing,running flexible

C:Acceptance standards

(1)The machine specifications must be consistent with the contract

(2)Extrusion output:Max 180kg/hr

(3)Coating thickness precision:±5﹪(coating 10-30mm,side 20mm)

(4)Max loss:the max is 3% in the normal operation,but except the following,

①Cut the scrap

②The unwinding and rewinding of paper connected

③Start and stop to run the machine

(5)The acceptance will be start after installing and commissioning

①No-load operation:Running two hours no load operation to confirm the machine if has abnormal sounds and heat.Note:The extruder can no load operation)

②Load operation

a)Test the extrusion output:Use the PE resin to test,the methods is to cut out 1 m2 laminating product at the rated speed,get the weight of PE lamination to calculate the extrusion capacity

b)Test the appearance:Rewinding is neat,products do not have wavy edges on both sides after unwinding

c)The width of laminating is steady,rewinding surface is neat

Spare parts

| Name | Quantity |

| Air tap of inflatable shaft | 2 pcs |

| Pipe joints,three way cock,straight through | each 2 pcs |

| Normal screw(kinds of spec.) | each 5 pcs |

| Filter heating piece | 4 pcs |

| T-Die heating rod | 2 pcs |

| Thermocouple | 2 pcs |

| A.C. contactor | 2 pcs |

| Relay | 2 pcs |

| Ampere meter | 1 piece |

| button | 5 pcs |

| Change over switch | 3 pcs |

| Indicator light | 3 pcs |

| Pressure regulating valve | 2 pcs |

Attachment tools

| tool | Quantity |

| 5.5-27 box spanner | 1set |

| 3-27 Internal hexagonal wrench | 1set |

| 8-10 Solid wrench | 1set |

| 200,375 Monkey spanner | each 1 |

| 6#磁性批一字,十字 | each 1 |

| 4#磁性批一字,十字 | each 1 |

| 8# plier,nipper plier | each 1 |

| 15M tape | 1 |

| Pneumatic gun | 1 |

Notes:As the technology is improving,the parts of machine will be changed,we have rights to improved.

Technical data and operation and maintenance and training and after service

一、Details of technical date

1.The foundation drawing of lamination machine(30 days after signing the contract)

2.Operation instruction (including operation and maintain)

3.Structure drawing of machine(Attached in the operation instruction

4.Electric circuit diagram,water and air pipes work diagram

5.Inspection certificate

6.Main parts operation instruction

7.Attachment tools,spare parts(Delivering the machines)

8.Technology and technological operation

9.Structure and technological selection

二、It takes about 15 days to install and debug the machine.After acceptance,company will send two technicians(mechanical and electrical each one) to train the buyer’s workers about 3-5 days. the buyer is responsible for the round-trip flight ticket for technicians, food and hotel, visa fees, transportation fee and technician salary 100 US dollars / day / person.(If the purchaser’s countries due to war,riots,infectious diseases,the disaster is not conducive to the safety of life, the saler does not provide installation,commissioning and technical support, the buyer should sent technician to saler's factory learning technologies for operation and installtion.the period of Install service for the purchaser received the machine in three months, if exceed this period time,saler will not provide this service)

三、Service commitment

1.The warrant of machine is one year from the date of leaving factory .Due to the manufacturing quality problems to damage the parts,seller will provide the free parts.(the matched auxiliary machine will not in warrant)

2.The Seller will make answer within 24 hours during the machine is in warranty time,if can not solve,should arrange to send the technician ASAP。

3.The seller can supply the advice when the buyer has problems in technological production.

四、To the improvements suggestions from buyer,the seller must be help to improve and answer actively.

If any specification is changed,please contact with us