Features:

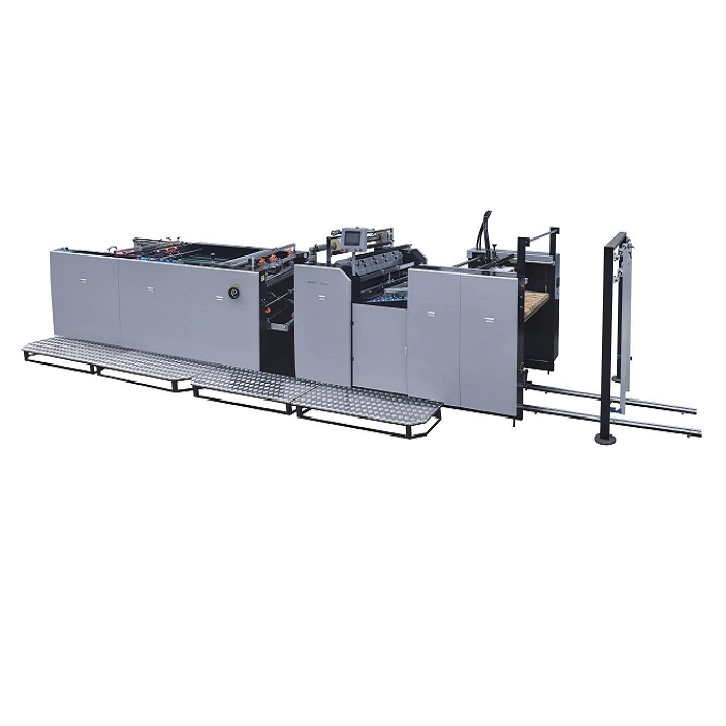

FMS-Z automatic water-based laminating machine uses water-soluble green glue, using BOPP film as material. After lamination, the product has high transparency, strong three-dimensional effect, non-toxicity, no smell, no pollution, good adhesive performance, no snowflake, no foaming, etc. Applicable paper and plastic surface laminating (such as: product brochures, textbooks, publishing new technology books and New Year pictures, calendars, various kinds of packaging boxes, etc.), strong adaptability to plastic film, is indeed the advanced equipment of paper products surface laminating .

Automatic feeder:

1.Automatic paper feeding system is equipped with no paper protector, paper break protector and paper superposing protector, which are controlled by photoelectric and mechanical systems. When no paper, paper break or paper superposition occurs, the machine will stop automatically for self-protection.

2.Pull guide with servo overlap system

Main part:

1.Automated operation is controlled by PLC system.

2.Planetary gear reducer with servo motor, so that the paper between before and after the overlap can be adjusted to ensure consistent coincidence.

3.Dip coating saves glue, and ensures glue coating homogenized. And the thickness of glue coating is adjustable.

4.Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle.

5.Serrated perforating wheel perforates film edge for the automatic cut of laminated paper.

Technical parameter:

|

Model |

FMS-Z1100 |

|

Min. sheet(WxL) |

325*325mm |

|

Max. sheet(WxL) |

980*1040mm |

|

Paper thickness |

128-500g |

|

Power required |

6KW |

|

Machine Speed |

0-75m/min |

|

Dimension(L x W x H) |

3700*1800*1750mm |

|

Weight machine |

2000kg |