Device Running Video:

YH Automatic screen printing machine

YH Series 4 color 4 dryer 10 station t shirt screen printing mahcine

Basic introduction:

YH series printing machine is the newest and most advanced new generation automatic printing equipment in China, which will bring you high output and fast investment return. Its main features include:computer micro-processing system,accurate printing color setting accuracy,electric printing head and pneumatic turntable lifting system, simple and fast net frame loading and unloading, independent scraping and printing ink recovery speed can be adjusted freely, the machine frame can install flocking printing head an dvivid touchscreen operation interface.The YH series is available in 4,6,8,10,12 and 14 colors, with a maximum printing area of 500 x 700 mm. All models can be printed on t-shirts, sleeves, sheets and textile bags.

Detailed characteristics:

1.Color touch screen operation interface

2.The servo drive system can provide high speed running speed while ensuring stable, durable and long service life of printing

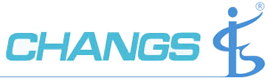

3.Quick pneumatic plat for mreplacement function

4.The turntable can rotate clockwise or counterclockwise

5.The net distance of all stations(the distance between the screen plate and the substrate surface) can be accurately adjusted at the same time

6.The frame should be able to assemble oven, printing head and flocking printing head as required

7.Manual tap jumping switch can avoid empty platform printing

8.Double shift function improves printing quality

9.The function of thick plate printing and automatic plate-changing is optional

Details show:

Parameters:

| Model | YH-104/8 | YH-156/10 | YH-158/12 |

| Print Color/Station | 4/8 | 4-6/10 | 4-10/12 |

| Maz. Image Area | 500×700/mm/600×800/mm | ||

| Pallet Size | 600×800/mm/700×900/mm | ||

| Frame Size | 720×1050/mm/820×1150/mm | ||

| Max.Air Consumption | 8P 24.71L/100mm(piston move) | 8P 24.71L/100mm(piston move) | 8P 30.44L/100mm(piston move) |

| Max.Output | 900pcs/h | ||

| Power | 2.9Kw | 4.4Kw | 4.4Kw |

| Each Dryer Power | 13.5Kw | ||

| Size | ∮4800×1650/mm | ∮5500×1850/mm | ∮5500×1850/mm |

| Weight | 2300Kg | 3000Kg | 3300Kg |

| Model | YH-1510/14 | YH-2012/18 | YH-2016/18 |

| Print Color/Station | 4-12/14 | 4-12/16 | 4-16/18 |

| Maz. Image Area | 500×700/mm/600×800/mm | 400×600/mm | |

| Pallet Size | 600×800/mm/700×900/mm | 500×700/mm | |

| Frame Size | 720×1050/mm/820×1150/mm | 620×950/mm | |

| Max.Air Consumption | 8P 31.51L/100mm(piston move) | 8P 30.44L/100mm(piston move) | 8P 34.91L/100mm(piston move) |

| Max.Output | 900pcs/h | ||

| Power | 4.4Kw | 5.5Kw | 5.5Kw |

| Each Dryer Power | 13.5Kw | ||

| Size | ∮6000×1850/mm | ∮6400×1850/mm | ∮7000×2500/mm |

| Weight | 3600Kg | 4300Kg | 5100Kg |

Electrical equipment configuration:

| Name | YH(Brand) |

| Touch Screen | DELTA(colorful 10 inch) |

| Power Switch | MEAN WELL |

| Servo Motor | YASKAWA |

| Transducer | DELTA(0.4KW/220V) |

| Smatch Switch | MOELLER(A22-FAK) |

| AC Contactor | (CHNT) |

| Middle Relay | OMRON(24VDC) |

| Proxity Switch | OMRON |

| Emergency Switch | SCHNEIDER(BE102C) |

| Switch With Lock | SCHNEIDER(BE101C) |

| Spin Switch | SCHNEIDER(BE101C) |

| Air Manometer | SMC |

| Special Cylinder | UNIQUC(Bidirectional cylinder) |

| Muffler | EASUN |

| Two-way | PNEUMAN |

| Two-way Valve | Mindman |

| Belt | Megadyne(Italy) |

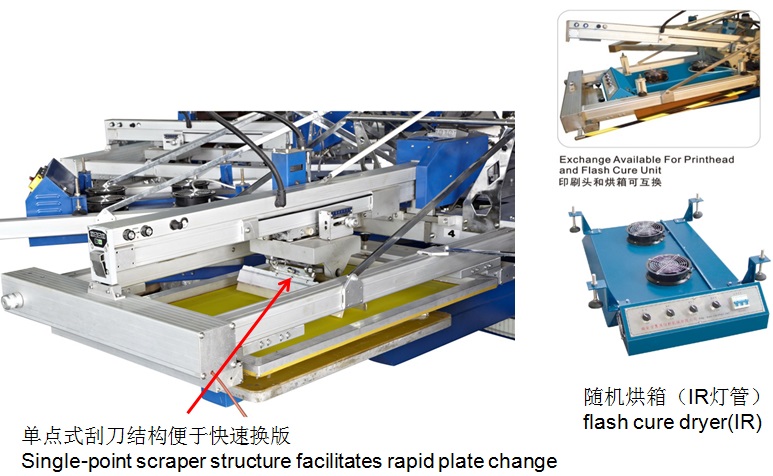

Printing process:

Other related ancillary equipment isalso required.

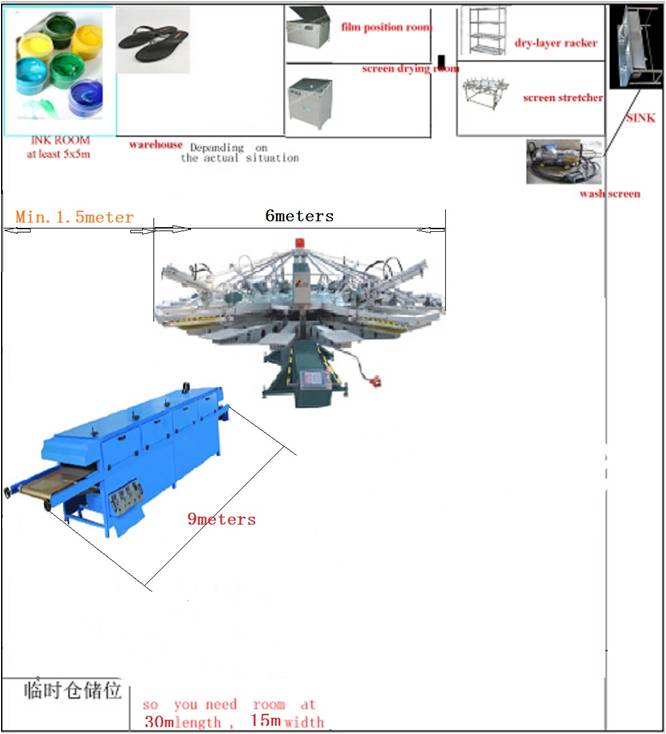

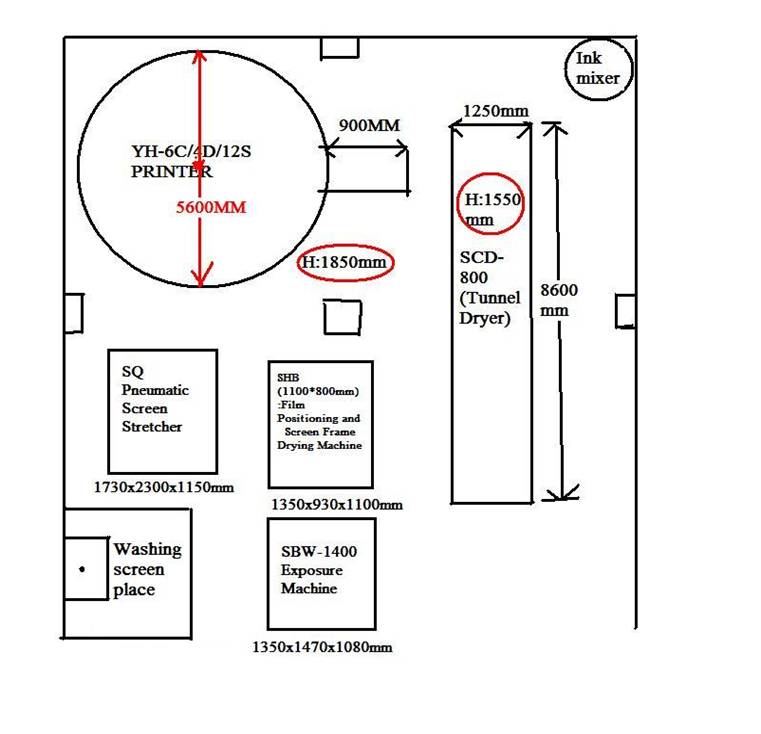

Workshop layout:

Relevant consumables and equipment:

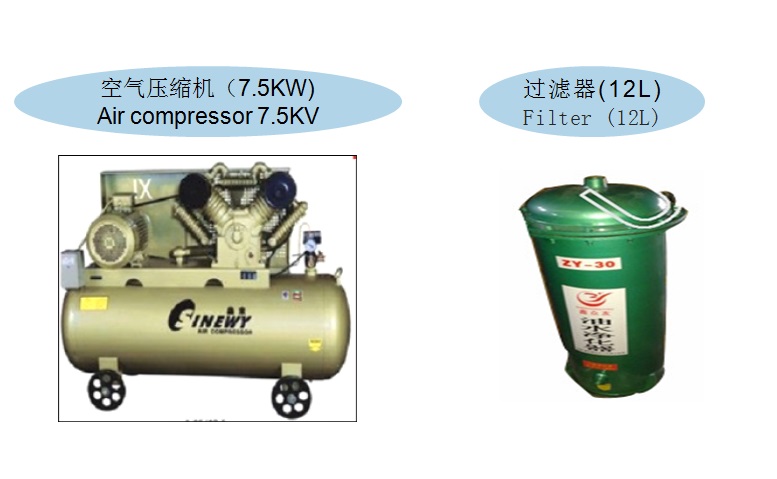

This machine needs to cooperate with air compressor and air filter,as well as other related auxiliary equipment.

Customer pictures: